Galvanized Steel in The Agricultural Industry

Metal and Farming: A Perfect Match

The union of farming and metalworking has led to many of civilizations technological and agricultural developments. Before the invention of farming, most early civilizations existed as gatherers and hunters. Because farming created the conditions in which people could settle, it ultimately contributed to the building of modern society and culture. Farming, and the stability farming provided humanity, led to the benefits of modernity: technology, politics, literature, the arts, and culture. Metal, like farming, helped to tilt the balance of power between mankind and nature towards mankind. Human beings could finally subdue the natural elements around them, which, beforehand, they seemingly had little to no control over.

Before the union of farm work and metal, farmers had inefficient tools to contend with the harsh conditions. These medieval farms only produced somewhere between 4.34 seeds for each seed of wheat sown. Entire village populations were constantly on the brink of starvation. Metalworkers introduced the iron plow to farmers, who had been using the ineffectual wooden plow. The new iron plows could cut through the heavy northern European soil, even during winter frost. This mingling of metal and farm work, among other technological/intellectual developments, led to the Enlightenment era and a population boom that reshaped the social order.

Today, the interaction between farming and metalworking continues to provide humanity with bountiful harvest. Although farms have become much more efficient, profit and competitive margins remain slim. Advances in metallurgy – like galvanized steel, are a keystone to modern farming operations by helping farmers to save time and money.

The Benefits of Galvanized Steel

Galvanized metal has been around for hundreds of years, although the methods for applying the zinc coating have become more sophisticated.

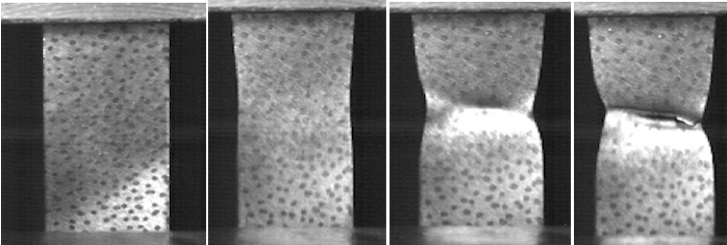

Galvanization improves steel’s longevity through a protective coating that prevents rust from forming. The process of hot-dip galvanizing creates a product with many benefits that other types of coatings don’t offer. For example, galvanized steel is:

- Less expensive when compared with most treated steels.

- Lower in maintenance cost than other coated metals – saving time on repairs and replacements.

- Damage-resistant, very durable, and can withstand outdoor elements.

- Self-healing in the way it’s coating provides automatic protection for damaged areas and will corrode preferentially to the steel, creating protection to the areas that are damaged.

Ready to use immediately upon delivery – it does not require additional preparation of the surface (painting/coatings, etc.) prior to installation.

[…]

[…]