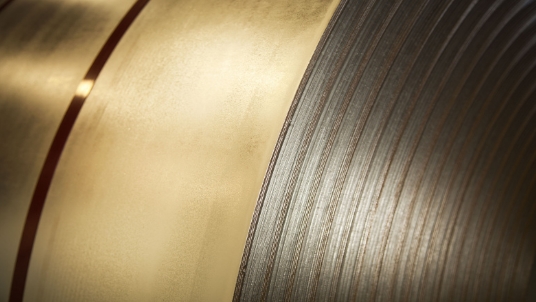

Pickling

Metal pickling is a process that is used to treat metal surfaces. It serves to remove impurities from the metal, including stains, rust, scale, and inorganic contaminants.

The use of high temperatures in metal working processing is common, but such processes can leave layers of oxidation on the surface of the material, which leads to staining and scaling. Metal pickling is used to remove these blemishes. To restore the best corrosion resistant performance, the damaged metal layer must be removed, exposing a fully alloyed stainless steel surface. The steel is dipped into a vat of the pickle liquor, and the acidity dissolves the stain.

Pickling removes embedded iron, weld scale, surface iron contamination, and heat tint from the material.

Capabilities

Materials: CSB, HSLA Grade 80, AHSS Gen 3 Steel, High Carbon 10B38 – 1095, High Silicon & Manganese Grades, 4000, 5000, 6000 series alloys including 6150.

Max Coil OD: Entry 80” / Exit 78”

Max Coil Weight: 74,000 lbs.

Max Strip Thickness: .500”

Min Strip Thickness: .039”

Min / Max Coil Width: 24-72”

Coil ID Min / Max: 16-36” / Exit 24” (30” Inquire)

In-Line Edge Trim Capabilities: Yes up to .250” / 1” of trim

Dry Lube & Repickling: Yes please inquire