Steel Service Snapshot: Advantages of Steel Blanking

The process of steel blanking has become prominent in the steel manufacturing industry because of its ability to make highly specialized parts that minimize waste and cost. With steel blanking, the goal is to use what is stamped/punched out rather than what is left after going through the die. Simply, the punched-out piece IS the part. Let’s look at how this process works, how it differs from other processes, and its overall benefits.

What is steel blanking?

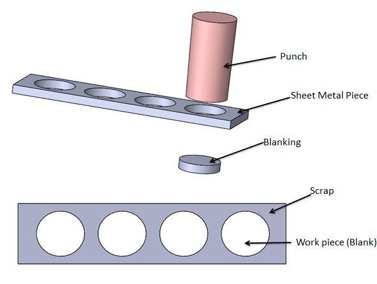

Blanking is a steel manufacturing process in which a flat, geometric shape (or “blank”) is created by feeding a coil of sheet metal into a press and die. In this process the blank is punched out from large metal sheet. Here is visual depiction of this process:

Press Blanking machinery can typically process material up to 72 inches (1828mm) wide and .250 inches (6.35mm) thick from coils up to 80,000 lbs. Typically multiple sheets are blanked in a single operation and the blanked parts will require secondary finishing to smooth out burrs along the bottom edge.

Press Blanking machinery can typically process material up to 72 inches (1828mm) wide and .250 inches (6.35mm) thick from coils up to 80,000 lbs. Typically multiple sheets are blanked in a single operation and the blanked parts will require secondary finishing to smooth out burrs along the bottom edge.

How does steel blanking differ from other process?

Other, similarly natured processes include punching and piercing. Both remove material from a metal sheet but the end results differ from steel blanking.

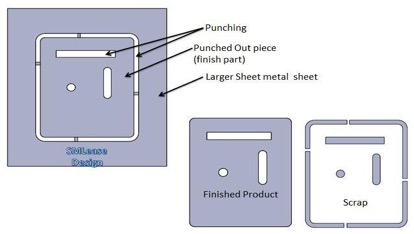

Punching is also a material removal process but rather than the final product being the punched out material, like in blanking, metal is removed so that the sheet metal itself is the final product. An easy way to differentiate is to think of a piece of paper that you punch a hole through. Blanking uses the circular piece as the final product while punching uses the piece of paper with the hole in it as the final product. Get a Custom Quote for Your Steel Blanking Needs

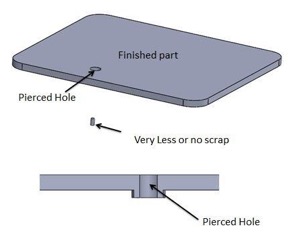

Another similar process is piercing, in which a punch operation cuts a hole by tearing operation from a final piece of sheet metal. This is process is considered a blanking operation.

Another similar process is piercing, in which a punch operation cuts a hole by tearing operation from a final piece of sheet metal. This is process is considered a blanking operation.

Steel Blanking Advantages

Steel blanking produces economical metal pieces that are customized to fit specific customer needs. In the blanking process the material is continually fed into the machine which leads toless setup and parts management. Simply, steel blanking allows you to make more with less.

This reduces waste significantly because the tools are typically designed to nest parts as close together as possible. Also, shipping costs are reduced by only sending the net weight and leaving the rest behind.

Industries that use steel blanking

Commonly, a press blanking line is designed to meet the

high-quality demands of the automotive and fabricating industries. This includes suppliers of “surface exposed” panels and other auxiliary sectors. The industries that use blanking material will likely expand. This is due to the ability for blanks to adapt to the final shape of the part which appeals to a wide variety of industrial industries.

NMC’s Steel Blanking Capabilities

National Material is a steel service center […]