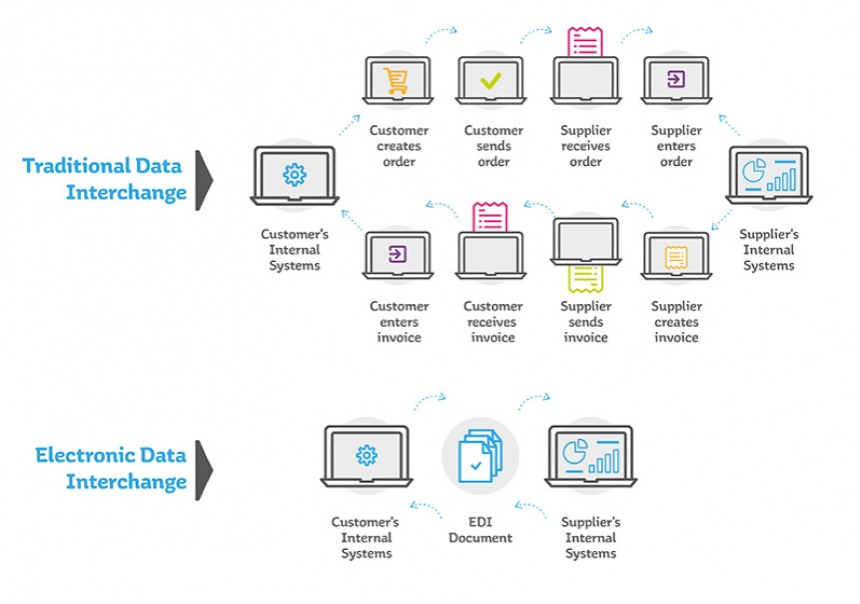

If your company takes part in supply chain processes, then you know how easy it is to lose control of the entire document flow and how important it is to have real-time access to reliable information regarding the delivery process. In traditional methods of business to business (b2b) communication, misunderstandings can often occur. Often, these misunderstandings are regarding collection and loading time, load capacity, product specificity, how the goods were packed and sent, and status of delivery. Manual entry data can result in incorrect documents, invoice totals can be erroneously entered, inaccurate invoice information can delay payment date, and delay receiving money to buy raw materials. Paper documents can become lost or filed in the wrong file and thus be difficult to find. Electronic data interchange, or, EDI, optimizes data exchange and management, and improves b2b communication and processes. EDI includes payment, invoices, delivery confirmation, delivery, packing, and ordering.

Like many other early information technologies, EDI was inspired by developments in military logistics. The complexity of military operations that required vast quantities of data and information about transported goods inspired the first innovations in large-scale communication, which later shaped the first TDCC (Transportation Data Coordinating Committee) standards in the United States. Among the first integrated systems using EDI were Freight Control Systems. An example of this is the London Airport Cargo EDP Scheme (LACES) at Heathrow Airport, London, in which a modem-like system would forward information to agents who would directly enter information into the customs processing system, reducing the time for clearance.

EDI provides a technical basis for automated commercial “conversations” between two entities, either internal or external. The term EDI encompasses the entire electronic data interchange process, including the transmission, message flow, document format, and software used to interpret the documents. EDI is the computer-to-computer exchange of business documents in a standard electronic format between business partners.

Each term in the definition is significant:

● Computer-to-computer – EDI replaces postal mail, fax, and email. While email is also an electronic approach, the documents exchanged via email must still be handled by people rather than computers. Having people involved slows down the processing of the documents and also introduces errors. Instead, EDI documents can flow straight through to the appropriate application on the receiver’s computer (e.g., the Order Management System) and processing can begin immediately.

● Business documents – These are any of the documents that are typically exchanged between businesses. The most common documents exchanged via EDI are purchase orders, invoices, and advance ship notices. But there are many, many others such as bills of lading, customs documents, inventory documents, shipping status documents, and payment documents.

● Standard format – Because EDI documents must be processed by computers rather than humans, a standard format must be used so that the computer will be able to read and understand the documents. A standard format describes what each piece of information is and in what format (e.g., integer, decimal, mmddyy). Without a standard format, each company would send documents using its own company-specific format and, just as an English-speaking person likely doesn’t understand Japanese, the receiver’s computer system doesn’t understand the company-specific format of the sender’s format.

● Business partners – The exchange of EDI documents is typically between two different companies, referred to as business partners or trading partners. For example, Company A may buy goods from Company B. Company A sends orders to Company B. Company A and Company B are business partners.

According to a recent research study from Forrester, EDI continues to prove its worth as an electronic message data format. This research states that “the annual volume of global EDI transactions exceeds 20 billion per year and is still growing.” For buyers that handle numerous transactions, using EDI can result in millions of dollars of annual savings, as well as other benefits. By moving away from a paper-based exchange of business documents to one that is electronic, businesses enjoy major benefits such as reduced cost, increased processing speed and accuracy, and business efficiency.

EDI provides businesses with savings because expenses associated with paper, printing, reproduction, storage, filing, postage, and document retrieval are all reduced or eliminated. Businesses avoid errors due to illegible faxes, lost orders, or incorrectly-taken phone orders, which also saves staff valuable time from handling data disputes. EDI can speed up your business cycles, as exchange transactions can happen in minutes instead of the days or weeks of wait time from the postal service.

With the significant reduction in transaction errors — errors from illegible handwriting, lost faxes/mail, and keying and re-keying errors — EDI is speedier than regular mail orders or phone orders. The increase in business efficiency is also a major factor, for example, automating paper-based tasks allows your staff to concentrate on higher-value tasks and provides them with the tools to be more productive. Quick processing of accurate business documents leads to less re-working of orders, fewer stockouts, and fewer cancelled orders. Automating the exchange of data between applications across a supply chain can ensure that business-critical data is sent on time and can be tracked in real time.

Most importantly, the greatest EDI benefits come at the strategic business level: EDI promotes corporate social responsibility and sustainability by replacing paper-based processes with electronic alternatives. Of course, going paperless saves both the buyer and seller money, but it also reduces CO2 emissions and the carbon footprint.

National Material and EDI

National Material Company (NMC) is proud to use EDI to increase your efficiency and accuracy. We:

● Automate transaction processing so that it’s faster and more accurate

● Eliminate keystroke and manual processing errors

● Reduce administrative costs

● Track orders throughout the supply chain

● Provide you with up-to-date information on your shipment and order status

● Improve relationships with the clearinghouse

Let NMC help you take advantage of the benefits of using EDI in your business!

NMC is a diverse operator of metal processing related services and is one of the largest independent operators of steel service centers in the United States. With more than 3,000 employees from a multinational portfolio of companies, NMLP provides engineered metal products which include aluminum extrusions and stainless steel rolled products to companies that supply automotive, aerospace, construction, defense, electrical, and industrial markets.

We produce and process our metals in-house, working directly with you to meet your specific needs while achieving time and cost savings. NMC specializes in supplying, servicing, and processing steel with unmatched efficiency due to our substantial list of capabilities including galvanized steel, advanced high strength steel, steel slitting, cold rolled steel, hot rolled steel, steel and metal processing, blanking, pickling, and cut-to-length processing, complete metallurgical lab and testing facilities, pre-painted steel rolling, galvanized, aluminized and other coated metals. Our steel processing capabilities also include: slitting, shearing, leveling, milling, saw cutting, drilling, flame cutting, tumbler, and burning.

About NMC’s parent company: NMLP

Since its founding in 1964, National Material Limited Partnership (NMLP) has grown to over 30 business units and is now one of the largest suppliers of steel in America. The National Material group of industrial businesses consists of the Steel Group, Stainless and Alloys Group, Raw Material Trading Group, Aluminum Group, and Related Operations.

Become an NMC customer today! Visit NMC at https://www.nationalmaterial.com/. Or you can contact sales via our website or call us at 847-806-7200.