Key Takeaways

- Adapting metal supply chains is no longer optional. Today’s manufacturers must build resilience through diversification, nearshoring, and circularity to stay competitive in a volatile global landscape.

- Strategic sourcing is built on proximity, sustainability, and partnership. Nearshoring, domestic metal sourcing, and circular supply chain models work best when integrated with strong, transparent supply chain relationships.

- NMC delivers resilient supply chain solutions. With advanced processing capabilities, regional facilities across North America, and a commitment to sustainability, NMC helps manufacturers build smarter, stronger metal supply chains.

Metal supply chains are being redefined by disruption. What used to be a stable, global logistics network is now subject to constant risk—economic swings, environmental demands, and geopolitical pressures have exposed the fragility of outdated systems. For manufacturers, adapting is no longer optional; it’s essential to staying operational and competitive.

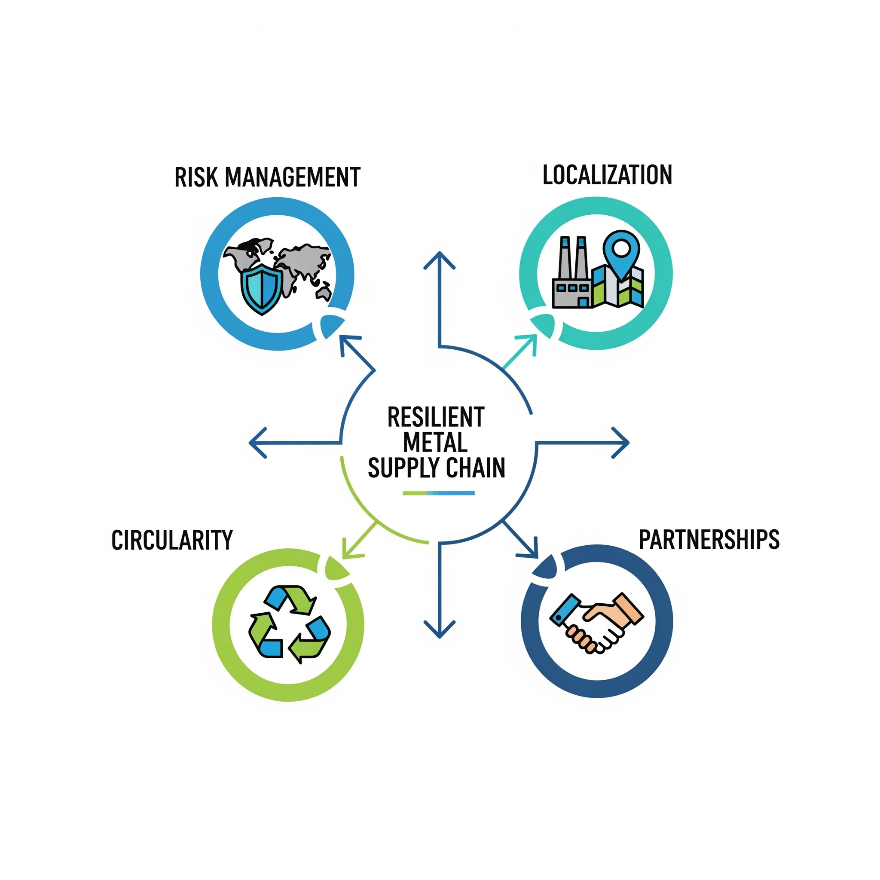

To meet this challenge, companies must rethink their entire approach—from raw material sourcing to recycling at end-of-life. Building resilient metal supply chains requires a dynamic strategy that incorporates domestic metal sourcing, nearshoring, circular supply chain metal practices, and strong supply chain partnerships. These elements must work together to deliver long-term stability and strategic value.

The Four Pillars of a Modern Metal Supply Chain

1. From Risk Mitigation to Strategic Advantage

Finding effective geopolitical supply chain solutions means moving beyond simply reacting to crises. For years, the industry mantra was ‘just-in-time.’ Today, that has shifted to ‘just-in-case.’ As Forbes notes, ongoing geopolitical tensions and economic instability remain top supply chain risks for 2025. Unpredictable tariffs and trade disputes can instantly make a low-cost overseas supplier the most expensive link in your chain.

Building a diversified supplier network is key. This means sourcing metals across multiple regions and using real-time data to monitor for disruption. Smart logistics and predictive analytics give companies the visibility to pivot quickly—whether facing a policy change, port strike, or severe weather event.

2. The Power of Proximity: Nearshoring and Domestic Sourcing

Long-distance metal supply chains carry risk. Nearshoring metal suppliers and investing in domestic metal sourcing create stronger links between production and processing. The closer the supplier, the shorter the lead time and the better the quality control.

This is especially critical in fast-moving sectors like Electric Vehicle (EV) manufacturing, where agile development cycles demand a responsive supply of specialized materials, such as electrical steel and high-strength steel. Relying on a supplier across the ocean can stall innovation. A North American strategy, for example, creates an ecosystem where raw material processing and manufacturing move in lockstep, boosting efficiency and resilience across the board.

3. Closing the Loop with a Circular Supply Chain

Today’s metal supply chains must go beyond efficiency—they must be sustainable. The outdated “take, make, dispose” model is being replaced by the circular supply chain, which aims to minimize waste and maximize the lifespan of materials. Steel is perfectly suited to this shift. As an infinitely recyclable material, it retains its strength and quality even after repeated processing.

Embracing a circular supply chain for metal supports ESG goals while offering a practical advantage: stability. By sourcing from partners that reclaim and reprocess scrap steel, companies reduce their reliance on volatile raw material markets. This not only reinforces supply chain strength but also aligns with increasing demands for eco-conscious products and transparent operations.

4. The Linchpin: Strategic Supply Chain Partnerships

Embracing a circular supply chain for metal supports ESG goals while offering a practical advantage: stability. By sourcing from partners that reclaim and reprocess scrap steel, companies reduce their reliance on volatile raw material markets. This not only reinforces supply chain strength but also aligns with increasing demands for eco-conscious products and transparent operations.

Strong supply chain partnerships enable effective nearshoring, circularity, and inventory management. These relationships foster transparency and joint problem-solving. When sourcing high-performance steel, the quality of the partnership determines the consistency, agility, and success of your entire operation.

NMC is Your Ally in a Resilient Metal Future

Understanding the pillars of modern metal supply chains is just the beginning. Putting them into practice takes a partner with both infrastructure and vision. National Material Company (NMC) delivers precisely that—supporting manufacturers with steel supply chain strategies designed for today’s challenges.

With facilities across North America, NMC enables nearshoring and domestic sourcing with reduced lead times and enhanced flexibility. Their advanced processing capabilities and smart logistics provide the real-time visibility required for risk mitigation. As a leader in circular supply chain metal solutions, NMC helps you meet sustainability goals without compromising performance.

Ready to Plan Smarter?

Before mapping out your next project, consider how different specifications can impact your material needs. Use these free steel calculators to get started.

When you are ready to build a truly resilient supply chain, contact NMC to speak with a specialist.