The rise of electric vehicles is an exciting trend, and aluminum is becoming an increasingly popular choice for their construction. Take, for instance, the Cosmic Motors Detonator featured in Daniel Simon‘s book Cosmic Motors: Spaceships, Cars, and Pilots of Another Galaxy. This incredible vehicle showcases the future of transportation, powered by electric motors that deliver lightning-fast speeds. Participating in the electric vehicles and aluminum movement is truly a thrilling time.

The impressive Cosmic Motors Detonator vehicle exemplifies aluminum’s utilization in transportation technology. This automobile serves as a glimpse into the future of space travel, where we may have the opportunity to travel through the cosmos in equally sleek and powerful vehicles. The electric motors of this car are based on real-world technology and can generate the necessary power to propel the vehicle at high speeds.

This article will delve into the many advantages of aluminum and its transformative impact on the future of electric vehicles.

What other materials are commonly used in electric vehicle construction besides aluminum?

Manufacturers use a variety of materials to construct electric vehicles, including:

- Steel : commonly used for chassis, body panels, and structural members due to its strength and durability

- Carbon fiber: used for lightweight and high-strength components like the battery enclosure, body panels, and wheels.

- Plastics: used for interior trim, bumpers, and other body panels.

- Copper: used for electrical wiring and components like the electric motor and battery pack.

Other metals, such as nickel, cobalt, and lithium, are used in the E.V. battery pack.

The materials used typically vary depending on the manufacturer and model.

Innovation in E.V. technology has led to the development of new materials and technologies, such as graphene, a lightweight and super-strong material, in E.V. batteries and other components.

As E.V. technology advances, we can expect to see the use of even more innovative materials in E.V. construction.

Aluminum for Electric Vehicles: Benefits of Aluminum in Electric Vehicles

Aluminum is an excellent option for reducing the weight of vehicles, as it weighs less than steel. Aluminum can make cars lighter, enhancing fuel efficiency and extending their range.

Although lightweight, aluminum is highly durable and can withstand driving forces. This makes it an excellent choice for structural components like the body-in-white. Harsh environments such as salt water and road salt can cause corrosion in electric cars, making it crucial to use resistant materials. Aluminum is known for its corrosion-resistant properties, making it an ideal choice to help extend the lifespan of electric vehicles.

Additionally, aluminum is 100% recyclable, which makes it an environmentally sustainable material for electric vehicles. Automakers who want to reduce their environmental impact should take note of this. Lastly, aluminum is a relatively low-cost material that can help keep the costs of electric vehicles down.

The Application of Aluminum in Electric Vehicles Today

With the growing demand, vehicle manufacturers are constantly looking for ways to improve the performance and efficiency of electric cars. One way to achieve this is by using aluminum in their construction. There are numerous examples of aluminum use in electric vehicles:

-

The body-in-white plays a crucial role in vehicles, encompassing the chassis, floor pan, and body panels. Electric cars increasingly rely on aluminum for this structure to enhance fuel efficiency and reduce weight.

-

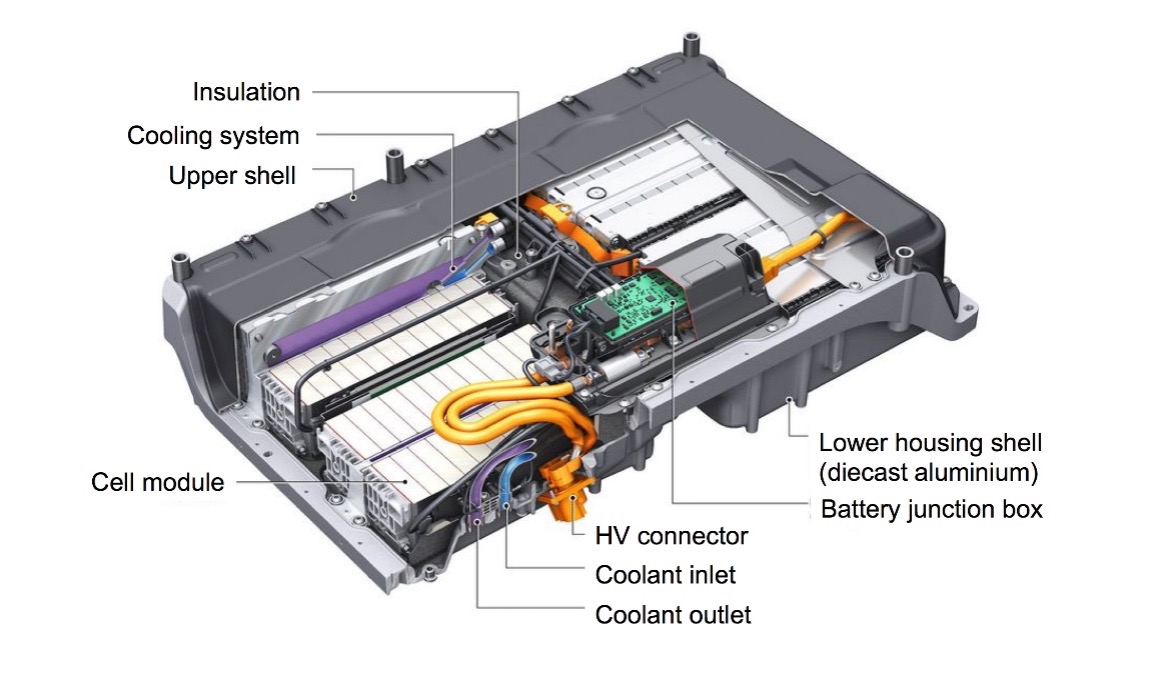

For battery housing in electric vehicles, aluminum is a trendy choice. Aluminum’s increasing demand for lightweight vehicles makes it highly energy-efficient, leading to longer driving ranges. Moreover, aluminum boasts exceptional thermal conductivity, facilitating heat dissipation and maintaining optimal battery temperatures. This helps prevent overheating, ensuring the battery performs optimally and lasts longer.

-

Aluminum wheels offer a lighter alternative to steel wheels, allowing for a reduction in the unsprung mass of a vehicle. Aluminum tires can improve handling, acceleration, and energy efficiency, but people do not widely use them.

-

Components such as the stator and rotor are often made of aluminum in electric vehicles.

More and more people are choosing electric cars, and experts predict that these vehicles will use even more aluminum in their construction.

Aluminum for Automotive: The Future of Aluminum in Electric Vehicles

The automotive industry is currently experiencing a surge in demand for lightweight vehicles. In response to this trend, the industry has turned to aluminum to enhance the fuel efficiency of cars. Furthermore, experts predict that aluminum will experience an increase in demand due to the growth of the electric vehicle market. The development of aluminum alloys explicitly designed for use in electric vehicles is likely to contribute to the continued growth of this market.

Automakers can enhance fuel efficiency and extend the range of electric vehicles by using aluminum as a construction material. National Material Company specializes in producing top-quality aluminum products that meet industry standards, making it the best choice for aluminum in electric cars. Choosing National Material Company will give automakers peace of mind, knowing they use the best automotive metal processing for their electric vehicles.

Upgrade your electric vehicle’s fuel efficiency and range with the best quality aluminum products from the National Material Company. Choose the trusted leader in automotive steel processors and ensure your car uses the highest quality materials. Contact National Material Company today to learn more.

About Parent Company National Material L.P.

National Material Company is part of the National Material L.P. family of companies. They have multiple steel service centers and processing facilities in the United States, Canada, and Mexico, and they ship over 2 million tons of steel annually.

Thanks to its extensive list of capabilities, NMLP is a pro at supplying, servicing, and processing steel with top-of-the-line efficiency and capacity. NMC is proud to be ISO and IATF certified, which includes strict safety requirements for the protection of their personnel.

If you would like to learn more about how National Material Company can help you, contact NMC via email at nmcquotes@nmlp.com, by phone at 847-806-7200, or by visiting their website.