Leading steel processor National Material Company, like the rest of the steel industry, is watching carefully as steel demand recovers in 2021. As the coronavirus pandemic affected all areas of the global economy, 2020 was a year like no other, and we are grateful for the cautious hope the new year brings.

As supply chains continue to stabilize, shipments of raw materials from other countries and manufacturing of parts has resumed. The World Steel Association says it expects steel demand to recover in 2021 to 1,717 million metric tons, an increase of 3.8 percent compared with 2020. The recovery of steel demand will be more visible in the second half of 2021, World Steel predicts, and will be driven by construction, especially infrastructure investment, as the government has put forward several new infrastructure initiatives.

What does this mean for American steel processors? According to a recent article in The Wall Street Journal, steelmakers idled about one-third of domestic production capacity for flat-rolled steel last spring when their customers canceled orders and closed plants to slow the spread of the new coronavirus. Since many factories reopened a month or two later, steel demand for cars, appliances, and machinery has rebounded, thanks, in part, to rising purchases from homebound consumers.

- From Nasdaq:

American steel stocks have seen recent gains on hopes that the sizable infrastructure spending would have a beneficial effect on the U.S. steel industry given the expected increase in consumption of the commodity that is used to make almost everything from rail tracks to roads to bridges and tunnels.

Steel makers are seeing strong order booking in automotive. Recovery in the automotive industry has accelerated following pandemic-led shutdowns on the back of strong customer demand. The automotive rebound is driving demand for flat steel products globally.

Moreover, the revival in the construction sector globally is driving demand for long and flat steel products in this major market. The construction sector has also bounced back on the heels of a resumption of projects that were stalled earlier due to supply chain disruptions and manpower shortage. In particular, the non-residential construction market remains resilient (read full article here).

Response to adversity is what will determine the outcome of the story. Historically, the American steel industry is as resilient as it gets, built on a foundation that literally supports our entire country’s infrastructure.

As OEMs and large companies that utilize steel processing services take another step forward into 2021, they may be wise to ask themselves, “Are there strategic partnerships that will strengthen competitive positioning and business resiliency?” After all, in the steel industry, great end products await at the end of the rainbow.

Alt tag: A warehouse with 2 rows of

Why National Material Company?

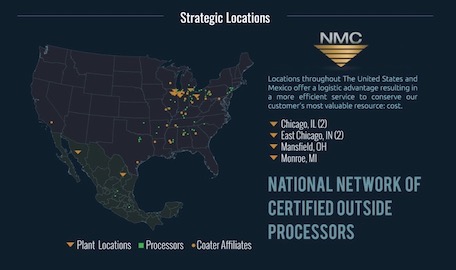

As a leader in steel processing capabilities, supply chain management, and inventory control, NMC is the perfect choice for any customer in search of the best experience possible. A dedicated workforce, state-of-the-art slitters, cut-to-length lines, and warehouse storage capabilities make NMC the premiere steel manufacturing company in North America. Locations throughout the United States and Mexico offer a logistic advantage resulting in a more efficient service to conserve our customers’ most valuable resource: money.

It is the appreciation of all moving parts that will make a client’s final product a commercial success. With expert supply chain management, just-on-time delivery, and access to all the right partnerships, NMC can deliver the right steel at the right time.

About National Material L.P. – Since its founding in 1964, National Material Limited Partnership has grown to over 30 business units and is now one of the largest suppliers of steel in America. The National Material group of industrial businesses consists of the Steel Group, Stainless and Alloys Group, Raw Material Trading Group, Aluminum Group, and Related Operations.

Please visit us at www.nationalmaterial.com or call (U.S.) 847-806-7200 to discuss how we can be of service.