Key Takeaways:

- Outsourced metal processing leads to delays, inconsistent quality, and higher logistics costs, disrupting production.

- In-house or integrated metal processing with just-in-time delivery improves speed, precision, and reliability.

- NMC offers end-to-end metal processing and supply chain coordination, reducing risk, improving quality, and saving time and cost.

Metal processing services are vital to strengthening supply chain reliability for manufacturers by ensuring that materials, schedules, and quality remain consistent. In today’s volatile market, where a single delay in metal delivery can halt production, greater control over each stage is increasingly prioritized, beginning with how metal is processed. Cutting, slitting, blanking, leveling, and finishing are the backbone of an efficient supply chain, allowing operations to flow more smoothly from start to finish. As global disruptions continue, precision and just-in-time metal processing minimize risk and maintain profitability. Ultimately, by leveraging in-house processing capabilities, greater control is achieved, costs are reduced, and the stability needed to remain competitive is secured.

Why Supply Chain Reliability Is Non-Negotiable

When a production line is dependent on a consistent sheet or coil supply, every hour of delay is a measurable cost. According to the American Iron and Steel Institute, even minor fluctuations in steel production are felt throughout automotive and construction supply chains. Moreover, as delivery premiums for aluminum continue to rise, transportation and logistics costs are linked to supply volatility.

Reliable supply chains minimize these shocks. They are founded on three critical elements: material availability, processing precision, and trusted vendor partnerships. Manufacturers that rely solely on outside vendors are confronted with blind spots, ranging from inconsistent quality to unexpected transport delays. Each handoff introduces risk. Integrating metal services closer to the point of use eliminates these weak links and creates more responsive systems.

Although the concept is not new, its urgency is amplified. Global reshoring, just-in-time manufacturing, and capital equipment cycles have all intensified the costs of downtime. Consequently, as OEMs impose tighter schedules and demand stricter tolerances, supply reliability is treated as a performance metric rather than a background assumption.

How Steel Processing Capabilities Build Supply Chain Strength

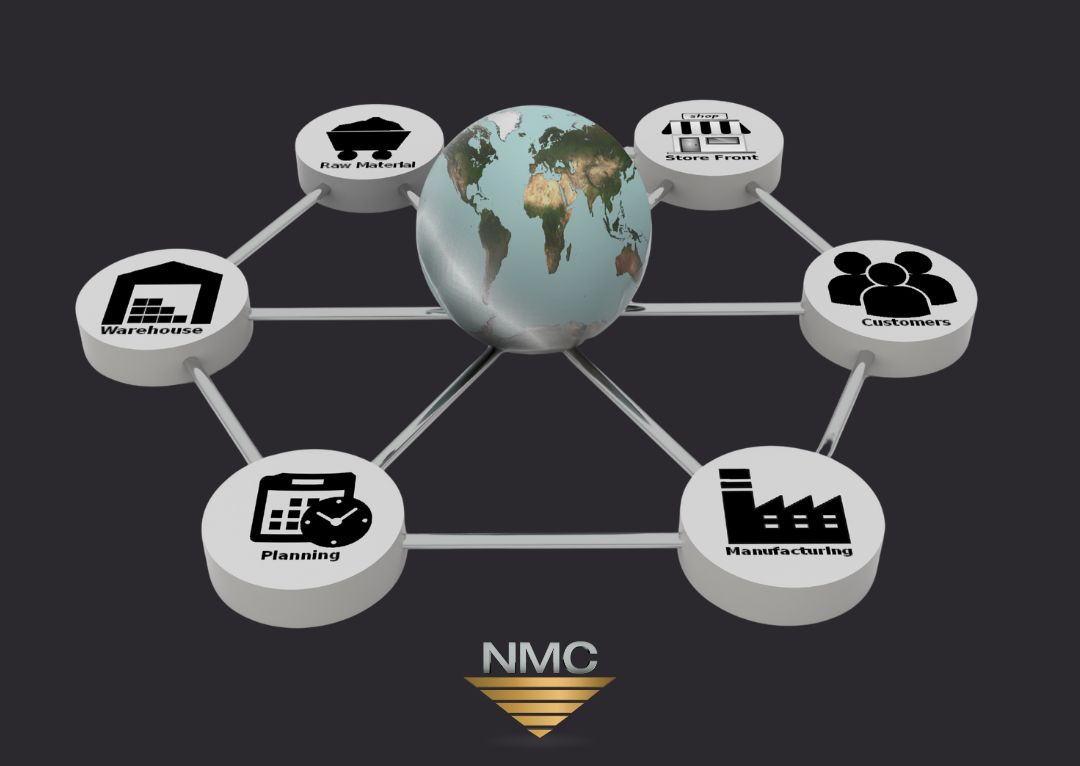

Supply chains are strengthened by improvements in three key performance levers: speed, precision, and consistency.

- Reduced transportation and handling costs: When cutting, slitting, or blanking is performed by the same partner managing raw coil supply, it eliminates redundant freight moves. Each avoided truckload reduces both time and cost.

- Shorter lead times: Lead times are significantly shortened when metal fabrication services are performed in-house or by closely partnered providers. Instead of shipping coils to multiple subcontractors, processing is conducted near the source or assembly point. Consequently, planning is streamlined, just-in-time delivery is supported, and production schedules are maintained without excess inventory.

- Better quality control and precision: Tighter processing control results in fewer rejections. Flatness, tolerances, and consistency are ensured through precision metal processing, allowing downstream operations to be trusted. Each rejected coil or off-spec blank is not just wasted material but lost uptime.

- Stronger vendor partnerships: Strategic metal processing partners are treated as extensions of the supply chain team. Forecasts are shared, capacity fluctuations are anticipated, and schedules are adapted before issues escalate. This approach mirrors what Greenway Steel describes as a “collaborative network,” while focusing on precision processing and real-time responsiveness.

Taken together, these advantages act as a shield against volatility. When suppliers are integrated and communication is clear, disruptions are minimized and recovery is accelerated. As noted by the U.S. Geological Survey, domestic processing capacity serves as a critical buffer against global supply constraints, a fact that is increasingly recognized by manufacturers after years of offshoring.

Precision and Just-in-Time Processing in Action

Just-in-time metal processing turns raw material into ready-to-assemble parts precisely when they are required on the production line. Its precision, combined with exact timing, directly enhances reliability. For instance, in the automotive sector, production runs are reliant on exact gauge, finish, and form being delivered in sequence. A single late delivery can stop an entire line.

These needs are proactively managed by integrated processors, with material readiness, process sequencing, and packaging coordinated to line-side demand. In an environment where lead times can dictate quarterly outcomes, foresight is emphasized by manufacturers working with industrial metal processing partners rather than merely reacting.

Additionally, industry data indicates that the metal processing market continues to grow, driven by aerospace, renewable energy, and infrastructure investment. This pattern suggests that reliability and control remains essential priorities even after short-term supply disruptions are diminished.

Why Manufacturers Turn to NMC

National Material Company (NMC) builds its reputation on making reliability measurable. Their integrated metal processing capabilities, including slitting, blanking, and supply chain coordination, allow customers to consolidate vendors and reduce logistical risk. OEMs and Tier-1 suppliers rely on NMC as a trusted industrial metal processing partner because they know delays are costly and precision isn’t optional.