Key Takeaways:

- Precision slitting reduces waste, ensures tight tolerances, and delivers materials ready for immediate use.

- Supports just-in-time manufacturing, lowering inventory costs and streamlining production.

- Benefits multiple industries, including automotive, appliances, construction, HVAC, and solar.

- Sourcing from North American slitting providers shortens lead times, improves quality oversight, and strengthens supply chain resilience.

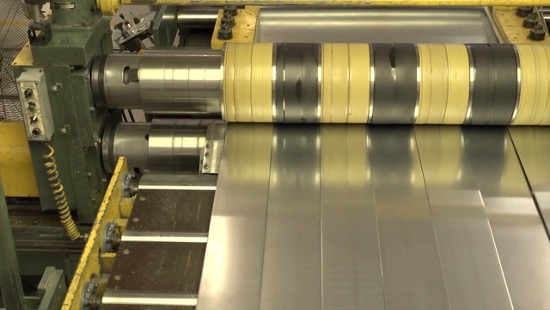

Precision slitting is helping Original Equipment Manufacturers (OEMs) meet growing demands to reduce waste, optimize supply chains, and maintain strict quality standards across industries ranging from automotive and appliances to solar and construction. This advanced coil processing method transforms master coils into narrow, tightly tolerance strips ready for stamping, forming, or fabrication.

When performed by experienced North American providers, precision slitting supports just-in-time delivery, reduces excess inventory, and ensures dimensional consistency—key to today’s lean, high-performance manufacturing operations.

A High-Value Solution to Modern Manufacturing Challenges

Aluminum slitting services demonstrate how strategic processing partnerships can meet unique material demands, particularly in sectors like automotive and solar. These services illustrate the flexibility and specialization required for high-performance applications.

Precision coil cutting bridges the gap between raw material supply and downstream fabrication. Meeting OEM demands means going beyond coil slicing to ensure the right product arrives at the right time, in the right way.

A precision slitting line processes various materials, including carbon steel, stainless steel, aluminum, and high-strength alloys, to achieve exact widths and tight tolerances. Modern high-accuracy coil processing equipment, such as advanced slitters, can handle various materials, from wide master coils to ultra thin foil, thanks to ongoing slitter design and automation advancements.

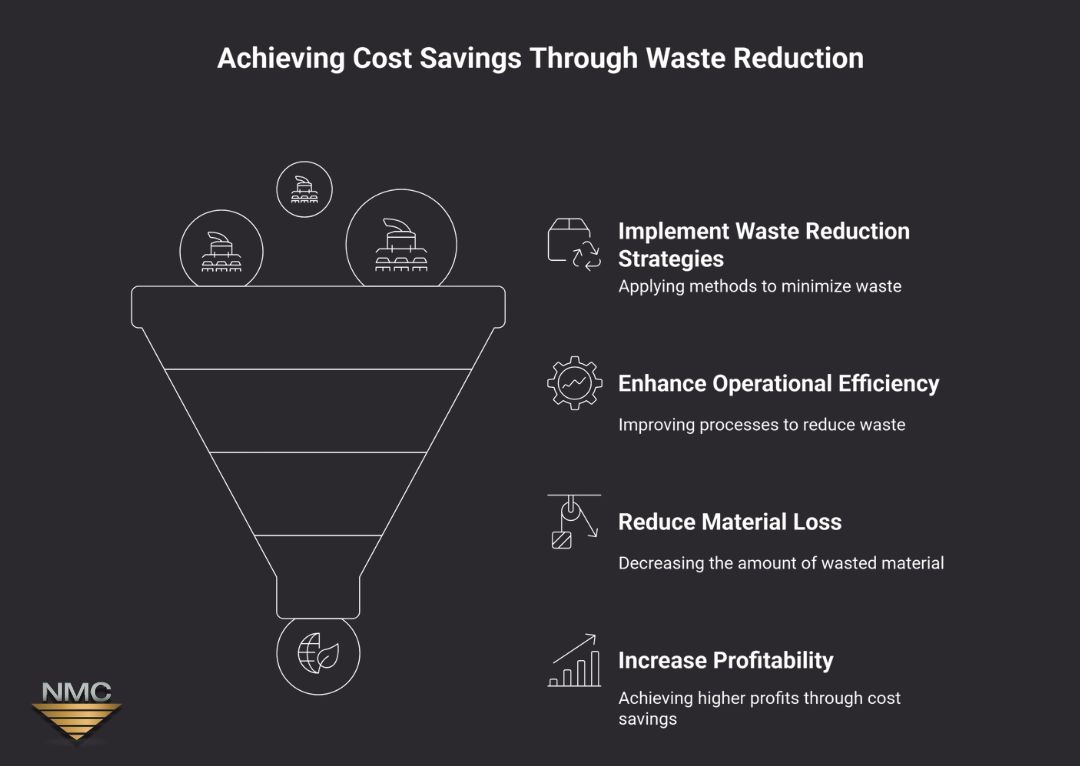

The Impact is Significant:

- Less material waste: Maintain tight tolerances to reduce overprocessing and minimize off-spec parts.

- Streamlined production: Materials arrive ready to use, cutting prep time.

- Smaller inventory footprints: With just-in-time precision slitting in North America, OEMs don’t need to warehouse oversized coils.

- Improved downstream efficiency: Fabricators and stampers receive uniform stock with clean edges, reducing tooling wear and improving uptime.

- Measurable cost reduction: For high-volume production, cost savings precision slitting steel coils are achieved by minimizing scrap, avoiding rework, and reducing unnecessary handling.

The value multiplies with coil processing services like edge conditioning, recoiling, or packaging. For OEMs managing complex supply chains, every step saved counts.

Industry-Specific Value: Automotive, Appliances, Solar, and More

Automotive

With EV adoption and lightweighting trends accelerating, exact-width slitting supports high-volume production of components from AHSS, aluminum, and composites. This precision minimizes burrs, splitting, and scrap while meeting demanding fuel efficiency and crash safety standards.

Appliances & Electronics

For stamped housings, interior brackets, and small components, uniform slit coils reduce variability and prevent assembly misfits. This enables lean manufacturing and supports white-label suppliers producing across multiple product lines.

Construction & HVAC

Structural components, ducts, and framing parts require consistent quality at scale. Local slitting services deliver cut-to-width galvanized or standard grades without the need for on-site cutting, reducing labor and material handling costs.

Solar & Renewable Energy

As solar installations rise, solar OEMs are pushing for tight material control. Coil processing services for solar fabrication help reduce waste in frame and mounting systems. U.S. slitting centers also support reshoring efforts as discussed in the SEIA report on rebuilding a domestic solar supply chain.

Why Local Coil Processing Makes a Difference

Partnering with North American coil processors offers strategic advantages:

- Shorter lead times

- Improved quality oversight

- Reduced shipping costs and emissions

- Faster response to design or volume changes

Most importantly, it strengthens supply chain resilience—reducing dependence on overseas sourcing and enabling faster, more reliable delivery to final assembly lines.

NMC: Precision Slitting That Performs

For over 60 years, National Material Company (NMC) has served as a backbone to U.S. manufacturing, offering precision slitting in North America through a network of high-capacity, high-accuracy coil processing facilities.

NMC Delivers:

• Slit coils with exacting tolerances

• A full menu of coil processing services, including packaging, inspection, and edge conditioning

• Support for key OEM industries, including automotive, construction, solar, and appliances

• Long-standing relationships with North American OEM metal suppliers

Before deciding on a slitting partner, try NMC’s free Steel Coil Weight Calculator, a useful tool for procurement and planning.