What are dual-phase steels?

Dual-Phase steels (DP steels) are a part of the Advanced High Strength Steel (AHSS) family.

Ferrite-Martensite dual-phase steel is a low-to-medium carbon material with between 5-50% volume fractional martensite islands that are dispersed in a soft ferrite matrix. In addition to martensite, bainite and retained austenite components can also exist; these are normally produced when improved edge stretch formability is desired.

These variations in microstructure give dual-phase steels a wide spectrum of strength and ductility. DP steels are known to be capable of absorbing large amounts of energy. Combined with a low cost of production, these properties make DP steels highly desirable for automotive applications.

Dual-phase steels can be produced as both hot rolled and cold rolled based material. When Hot Rolled, the rolling temperature and cooling process on the Hot Strip Mill is carefully controlled to produce the ferrite-martensite structure from austenite. When Cold Rolled, the properties are developed on Continuous Annealing lines where there is even greater control over thermal treatment.

DP Steels can be also produced as HD Galvanized, HD Galvannealed and Electro Galvanized.

Properties of DP steels

Both Hot and Cold-rolled DP steels offer an incredibly advantageous combination of low yield, high-tensile strength, easy cold working, and weldability due to their ferrite-martensite imbued lattice microstructure.

The carbon content of dual-phase steels enables the formation of martensite at practical cooling rates, which increases the hardenability of the steel. Generally, higher carbon will promote a stronger steel and a higher fractional percentage of martensite.

In DP steels the soft Ferrite phase is generally continuous, giving these steels excellent formability. When DP deforms the strain is concentrated in the lower strength Ferrite phase surrounding the hard islands of Martensite, which creates the very high initial work hardening rate exhibited by these steels.

Due to high-strain hardenability, dual-phase steels also have a high-strain redistribution capacity. This means improved drawability as well as finished part mechanical properties (yield strengths) that are higher than the initial blank.

DP steels also have a bake hardening effect that is an important benefit over conventional HSLA type materials. The bake hardening effect is the increase in yield strength resulting from elevated temperature aging created by the curing temperature of the paint bake cycle.

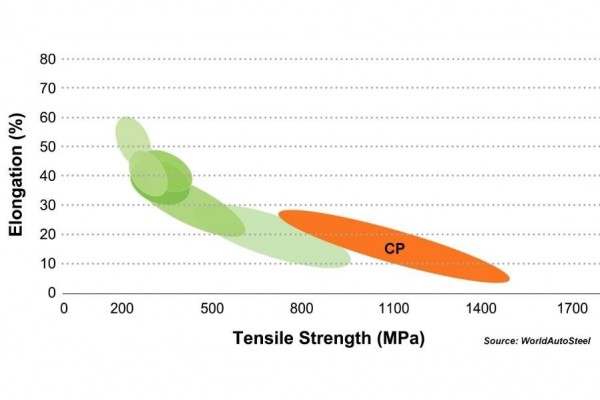

DP grades are currently being produced from 500 to 1200 Mpa minimum tensile strength with 5-35% total elongation.

Formability

DP steels offer an excellent combination of strength and drawability as a result of their strain hardening capacity from the beginning of deformation. This capability ensures homogeneous strain redistribution and reduces local thinning.

Dual-phase steels can be drawn on conventional tools, provided the settings are properly adjusted. For example, drawing pressure may be increased by approximately 20% for a Dual-Phase 600, compared to a micro-alloyed (HSLA) type steel of the same thickness.

Applications in Automobiles

As one could expect from a material with a high-tensile strength, dual-phase steels are well suited for automobile parts that are meant to absorb a lot of energy during an impact.

Dual-phase steels are often used in the following automobile applications:

- DP300/500 Roof Outer, Door Outer, Body Side Outer, Floor Panel

- DP350/600 Floor Panel, Hood Outer, Body Side Outer, Cowl, Fender, Floor Reinforcements

- DP500/800 Body Side Inner, Quarter Panel Inner, Rear Rails, Shock Reinforcements

- DP600/980 B-Pillar, Floor Panel, Engine Cradle, Seat Rails

- DP700/1000 Roof Rails

About National Material L.P. – With more than 3,000 employees from a multinational portfolio of companies, NMLP provides engineered metal products, which include steel processing, aluminum extrusion and stainless steel rolled product companies, to automotive, aerospace, construction, defense, electrical, and industrial markets.

Visit National Material: https://www.nationalmaterial.com or call (U.S.) 847-806-7200, Diana Pulido