Key Takeaways:

- Separate steel and aluminum supply chains drive higher costs, inconsistent quality, and greater vulnerability to disruption.

- Consolidating both materials under one metal processing partner streamlines logistics, standardizes quality, and reduces risk.

- Partner with a company that provides integrated steel and aluminum metal processing solutions through strategic inventory, advanced equipment, and just-in-time supply chain expertise.

Metal processing solutions have rapidly shifted from a forward-thinking concept to an operational necessity as steel and aluminum have long been managed through separate, parallel supply chains. This siloed model, while once functional, is now associated with increased friction, cost, and risk across modern industrial operations. As industries such as automotive and advanced manufacturing are pushed to balance aluminum’s lightweight benefits with steel’s strength, this fragmented approach is becoming less sustainable. Moreover, growing emphasis on efficiency and supply chain resilience is being driven by OEM priorities looking toward 2026. Consequently, a unified approach to metal processing is being adopted to simplify logistics, improve manufacturing efficiency, and support a more resilient, integrated supply chain.

The Fragmentation Problem: Why Separate Steel and Aluminum Supply Chains Are Inefficient

In complex manufacturing operations, the supply chain is often treated as the central system through which performance is determined. When that system is fragmented, inefficiencies are amplified across operations and finances. As steel and aluminum are sourced from separate metal service centers, redundant freight costs, duplicated carrier negotiations, and multiple delivery schedules are introduced. Subsequently, inventory management is complicated, with separate buffers being maintained, higher capital being tied up, and facility footprints being expanded.

Meanwhile, quality and compliance risks are increased as separate QC standards, tolerances, and reporting systems are applied by each supplier. As a result, duplicated compliance efforts and greater part-to-part variability are encountered by OEMs. Furthermore, this fragmented approach is left highly exposed to volatility, where a single disruption can halt production. Although traditional procurement models were once relied upon, they are now being re-evaluated in favor of more resilient strategies. When steel and aluminum are positioned on separate logistical paths, exposure to disruptions, from port delays to mill-level constraints, is effectively doubled.

Strategic Advantages of an Integrated Metal Processing Partner

The solution to fragmentation is integration. When both steel processing and aluminum processing are consolidated under a single metal processing partner, risk is reduced and workflows are streamlined across the organization. In addition to simplified invoicing, logistics, expertise, resilience, and quality are strengthened through a unified approach.

- Streamlined Logistics and Cost Control

Logistics and cost control are enhanced. Freight is consolidated, transport costs are reduced, and mixed-material truckloads are optimized. Consequently, a single point of contact for scheduling is established, and administrative burden on procurement and logistics teams is significantly lowered.

- Material-Agnostic Expertise

Material-agnostic expertise is applied. As demand for industrial aluminum increases alongside continued reliance on advanced high-strength steel, processing decisions are guided by application needs rather than material bias. The correct material is selected and processed according to established industry standards, such as those from the Aluminum Association and the American Iron and Steel Institute. With broad processing capabilities across both materials, conflicting requirements are navigated without the limitations of a single-material supplier.

- Enhanced Resilience and Flexibility

Resilience and flexibility are improved through unified oversight. With full visibility into total metal demand, more intelligent inventory strategies are enabled, and production priorities can be shifted when delays occur. As a result, continuity is supported, and assembly lines are kept operational in ways that siloed suppliers cannot match.

- Superior Quality and Consistency

Lastly, quality and consistency are strengthened under a single, unified standard. Both steel and aluminum are processed on calibrated equipment through one quality system. Thus, supplier-to-supplier variation is eliminated, and a more consistent, compliant product is delivered.

Building a Truly Smarter Supply Chain

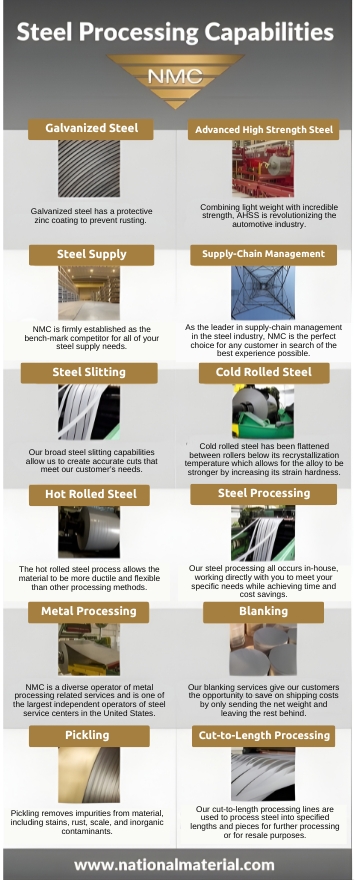

Achieving true integration requires a partner with proven capabilities. Not only must state-of-the-art slitting, blanking, and leveling equipment be in place for both materials, but advanced supply chain systems must also be maintained to manage complex B2B manufacturing demands. Therefore, a dedicated metal service center with deep experience across both steel and aluminum becomes essential.

This role has been defined by National Material Company (NMC), where operations have been built around delivering comprehensive metal processing solutions. A strategic inventory of both steel and aluminum is maintained, enabling OEMs to source flat-rolled material through a single, unified channel. In addition, extensive experience in managing just-in-time supply chains for automotive and industrial markets positions NMC as a true strategic partner rather than a transactional supplier.

As a result, purchasing agents and engineers are freed from daily supplier management and are instead supported in focusing on long-term, strategic objectives. Greater stability and predictability are introduced, allowing innovation to be pursued within a more efficient and resilient supply chain.

Before optimizing procurement, it’s vital to have the correct data. Engineers and purchasing agents can utilize this complimentary suite of Steel Calculators to estimate material weights and dimensions accurately.

To learn how an integrated approach to steel and aluminum processing can strengthen your industrial supply chain, contact a specialist at National Material Company.