Key Takeaways:

- A resilient steel-supply chain starts with domestic sourcing, flexible logistics, and value-added services that reduce risk and improve efficiency.

- Technology and sustainability play a critical role — real-time tracking, predictive tools, and eco-friendly practices support long-term supply chain success.

- National Material Company offers tailored supply chain solutions for OEMs and distributors, combining advanced steel processing with dependable U.S.-based logistics.

The phrase “strong as steel” takes on new meaning in terms of material strength and the resilience of the supply chains that deliver it in today’s volatile global market. For industries reliant on metals like steel and aluminum, disruptions can ripple through operations, causing delays, cost overruns, and lost opportunities. Whether you’re an engineer sourcing materials for a critical project or a purchasing agent securing supplies for an original equipment manufacturer (OEM), understanding how to build a resilient steel supply chain is no longer optional, but essential.

The Importance of Supply Chain Resilience in the Metals Industry

- Why steel supply chains are vulnerable

Today’s steel supply chain is a complex system — spanning raw material extraction, processing, transportation, and delivery. At every stage, risks such as geopolitical shifts, natural disasters, labor shortages, and shifting trade policies can cause costly disruptions. With mandates like Buy America driving demand for domestic steel sourcing, manufacturers are rethinking their approach. Logistics inefficiencies and freight delays often strain even the strongest aluminum supply chain, underscoring the need for regional suppliers and agile distribution strategies.

At the same time, sustainability is reshaping the metals supply and logistics sector. Stakeholders are adopting greener practices — prioritizing carbon transparency, recycling initiatives, and energy-efficient processes — to meet rising regulatory and consumer expectations. In this environment, supply chain resilience depends on more than availability — it demands adaptability and accountability.

- Lessons from recent disruptions

The pandemic revealed just how fragile global supply chains can be — clogged ports, factory shutdowns, and indefinite lead times left many scrambling. In response, North American distributors shifted to regional supply chain solutions and diversified their networks. According to the Aluminum Association, companies that adopted localized procurement saw 30% fewer disruptions.

Takeaway? Resilience means adaptability. Businesses that invested in advanced steel processing for OEMs, inventory optimization, and real-time logistics visibility outperformed those relying on outdated systems. Deloitte’s global report on supply chain resilience backs this up — organizations leveraging data and technology are more agile and less vulnerable to disruption.

Strategies to Build a Stronger Metals Supply Chain

- Strategic sourcing: think local, act global

Domestic sourcing has become a cornerstone of steel supply chain resilience. By prioritizing domestic steel sourcing, companies reduce dependency on foreign markets while supporting local economies. This approach aligns with federal initiatives like Buy America, which encourage the use of U.S.-produced materials in infrastructure and manufacturing projects.

For OEM steel suppliers, local partnerships with value-added services — such as precision slitting, custom blanking, and just-in-time delivery — enhance supply continuity and production efficiency. This localized strategy not only supports resilience but also drives long-term success through trusted, integrated collaboration.

- Logistics optimization: smoothing out the kinks

Efficient logistics are the backbone of a resilient steel supply chain. Leveraging data analytics, real-time tracking tools, and predictive modeling helps identify inefficiencies before they escalate. The Federal Highway Administration notes that freight bottlenecks and transportation inefficiencies significantly hinder national productivity.

Additionally, multimodal transportation combining rail, truck, and air freight offers flexibility when one mode faces disruption. A case in point was the 2021 Suez Canal blockage. Companies relying solely on maritime routes suffered significant losses. A report by the University of Gothenburg estimated that Maersk Line alone incurred losses nearing $89 million. In comparison, global trade losses reached as high as $15 to $17 billion due to over 400 delayed vessels. Those utilizing alternative channels mitigated risks effectively.

Flexibility Through Supply Chain Solutions

Flexible supply chain solutions like custom cutting, coating, and packaging further strengthen metals distribution frameworks. These offerings allow OEMs to receive materials tailored to their specifications, eliminating waste and saving time. For example, a construction firm building skyscrapers might require pre-cut beams delivered directly to the job site. Partnering with a provider offering such capabilities streamlines workflows and enhances productivity.

To boot, embracing digital platforms for ordering and tracking materials adds another convenience layer. Online portals enable customers to place orders, track shipments, and access documentation, all from a single interface. This level of transparency builds confidence and loyalty among stakeholders.

How National Material Company Supports Your Supply Chain Needs

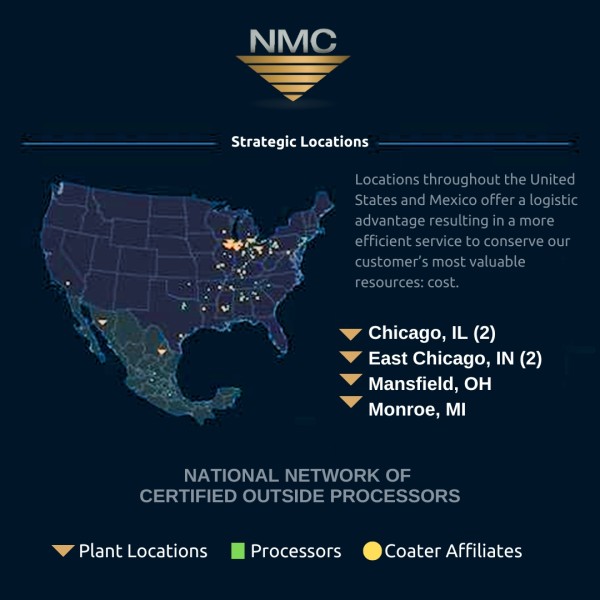

Building a resilient steel supply chain takes more than strategy — it requires the right partner. National Material Company (NMC) delivers comprehensive support through value-added metal services, advanced steel processing for OEMs, and full-spectrum supply chain solutions. As part of the NMLP family, NMC offers wide-ranging services designed to meet the unique needs of North American distributors, OEMs, and other industry players.

From state-of-the-art steel processing capabilities to comprehensive supply chain management, NMC ensures seamless operations at every stage. Their commitment to sustainability shines through initiatives promoting transparency and eco-friendly practices. For example, their focus on recycling scrap metal reduces waste while conserving natural resources, which is a win-win for businesses and the planet.

NMC provides a free consultation to help you assess your current supply chain strengths and weaknesses. Their experts will analyze your processes, identify areas for improvement, and recommend tailored solutions to boost resilience.