Roll forming plays a critical role in the steel manufacturing industry by shaping steel products in a way that can significantly impact their strength, durability, and performance. As you look around, you’ll notice that every object has a shape that distinguishes it from others, and this is equally true for steel products. From the curves and angles of a car frame to the outline and contours of a building’s roof, this process plays a vital role in shaping our world.

That’s why we’re putting roll forming in the spotlight and showcasing how National Material Company (NMC) leads the industry in this process.

Roll forming is a manufacturing process that is commonly used in the steel industry to shape sheet metal into various cross-section profiles. In a nutshell, it’s a continuous process that involves passing a metal strip or sheet through a series of rollers. This method is highly precise, and the rollers are designed and/or calibrated to gradually shape the material – making complex shapes possible with tight tolerances and consistent quality.

How Roll Forming Changed the Steel Industry

Its origin can be traced back to the late 19th century when the first roll forming machines were developed in Europe and the United States. These early machines were used primarily for producing simple shapes, such as roofing panels and gutters, and were powered by manual or hydraulic systems.

Prior to the invention of this process, shaping metal into various forms was a labor-intensive process that required skilled craftsmen to forge, cast, or fabricate the material by hand. Some of the most common processes used are forging, casting, extrusion, machining, and stamping.

While these processes are still used today for certain applications, roll forming offered several advantages over these traditional methods, including faster production times, lower labor costs, and the ability to produce more complex shapes and profiles. By feeding a continuous strip of metal through a series of rollers, roll forming machines could produce long, uniform sections of material with a high degree of accuracy and repeatability.

Roll Forming Process

Determining the specifications for the profile – in addition to form and function – is the initial stage of the production process. This includes the material type, thickness, width, length, and the desired cross-sectional shape.

The profile is then sketched out in 2D, or 3D using CAD (computer-aided design) software and should meet the specific requirements – including any tolerances or other design constraints. A flat pattern (two-dimensional representation) is then created and shows how the profile will look when it is unrolled into a flat sheet.

The next step is to add the necessary tooling to the forming machine. This includes the rollers, guides, and other components that are required to produce the profile. Once the profile design is complete, it is simulated using roll-forming software to ensure that the design is feasible and that the tooling is correct. Once the design is finalized, a prototype of the profile is produced and tested to ensure that it meets the desired specifications – this allows calibrations to the design or tooling to fine-tune – minimizing waste and increasing production efficiency.

The process involves careful planning, simulation, and testing to ensure that the final product meets the desired specifications. Overall, designing profiles requires a combination of engineering expertise and CAD software.

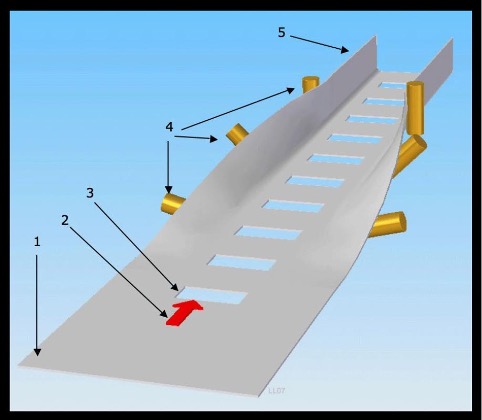

In general, here’s how the forming process goes:

-

Coil Preparation:

A steel coil is loaded onto the uncoiler, which is the first station in the roll-forming machine. The coil is then fed through the machine using a series of rollers that guide the steel through the different stages of the process.

-

Forming:

As the steel moves through the rollers, it is gradually bent and formed into the desired profile. The rollers are arranged in pairs, with each pair performing a specific bending or forming operation.

-

Cutting:

Once the steel has been fully formed, it is cut to the desired length. The cutting can be done either in line with the roll forming process or in a separate operation.

-

Finishing:

The finished part is then inspected for quality and any necessary finishing operations are performed, such as punching or notching.

-

Packaging:

Finally, the finished profiles are packaged and prepared for shipping.

The machine can also be equipped with additional stations for punching, notching, and other secondary operations. Overall, roll forming is a versatile and efficient process for producing high-quality profiles from steel coils.

Materials

Roll forming is a versatile manufacturing process that can accommodate a range of metals depending on the desired characteristics of the final product. Among the most commonly used metals are steel, which is valued for its strength and durability, aluminum for its lightweight and corrosion-resistant properties, copper for its malleability and electrical conductivity, brass for its decorative qualities, and stainless steel for its resistance to corrosion and ability to maintain a high level of cleanliness. Overall, the choice of metal used in roll forming will depend on the specific requirements of the final product, including its strength, durability, corrosion resistance, and appearance.

Limitless Applications

Roll-forming technology has continued to evolve and improve throughout the years with the introduction of new materials such as stainless steel, aluminum, and advancements in automation and computer technology.

Today, roll forming is a widely used process for producing a wide range of metal products, from simple shapes to complex profiles, and is used in industries ranging from construction and automotive to aerospace and consumer goods.

-

Construction

This process is commonly used in the construction industry to produce structural components such as roof and wall panels and metal decking among others.

-

Automotive

Complex shapes and profiles with tight tolerances make roll forming an ideal process for producing automotive parts such as frames, bumpers, and structural components.

-

Aerospace

Lightweight and high-strength parts make roll forming suitable for aerospace applications including aircraft frames, fuselage frames, wing ribs, engine components, and structural parts.

-

Electrical

This process is used in the electrical industry for applications such as conduit, cable trays, and electrical enclosures. Roll forming makes uniform profiles with precise dimensions ideal for producing electrical components.

-

Agricultural

When using corrosion-resistant steel, grain bins, storage tanks, and livestock equipment are more durable which makes roll forming perfect for agricultural applications.

-

Furniture

This process is used in the furniture industry to produce metal frames and components for chairs, tables, and other types of furniture.

To sum it all up, roll forming steel offers several benefits over other metal-forming processes. The invention of roll forming was driven by the growing demand for metal products in a variety of industries, including construction, transportation, and manufacturing. With the ability to produce metal products more quickly and efficiently, roll forming helped to fuel the growth of these industries and contributed to the development of modern infrastructure and technology.

About National Material Company

Here at National Material Company, we pride ourselves in being an industry leader in the rolled steel market by providing cost and time-effective solutions with steel service centers across the United States, Mexico, and Canada. NMC is a well-recognized global leader servicing the needs of the steel industry and leading industrial and consumer product manufacturers. With over 50 years of expertise, we’d love to realize your vision with our wide array of capabilities.

NMC is part of the National Material Limited Partnership (NMLP) steel division, which is one of the largest independent steel service centers in the United States. NMLP operates 16 steel service centers and processing facilities in the United States, Canada, and Mexico and ships over 2,000,000 tons of steel annually.

Please contact us at nationalmaterial.com, email us at nmcquotes@nmlp.com, or call (U.S.) 847-806-7200 to discuss how we can be of service.